+86 134 0021 8776

+86 134 0021 8776

News

Mar. 24, 2023

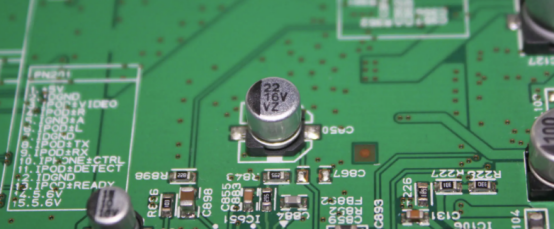

PCB solder resistance ink according to the curing method, solder resistance ink has photosensitive development ink, thermosetting ink, and UV photocurable UV ink. And according to the board classification, there are PCB hard plate solder resistance ink, FPC soft plate solder resistance ink, and aluminum substrate solder resistance ink, aluminum substrate ink can also be used on ceramic plate.

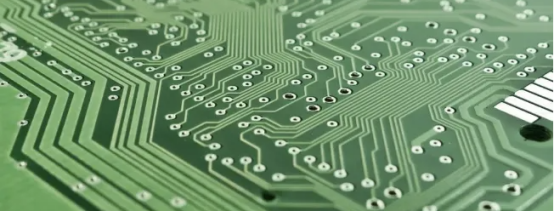

Through holes are generally divided into three categories: blind holes, buried holes and through holes. The "blind holes" are located on the top and bottom surfaces of the printed circuit board, with a certain depth, and are used to connect the surface circuit to the inner circuit. "Buried holes" are connection holes in the inner layer of the circuit board, which are not visible on the surface of the circuit board. The "through hole" runs through the entire circuit board, from the top layer to the bottom layer.

In the process of PCB welding resistance, common perforating processes include: perforating cover oil, perforating plug oil, perforating window opening, resin plug hole, electroplating hole filling, etc. Each of the five processes has its own characteristics, its own role and corresponding application scenarios.

1, through the hole cover oil

Through hole cover oil refers to through hole cover ink, no tin above the pad, most of the circuit board uses this process. The aperture of the design of the hole cover oil is not recommended to be greater than 0.5mm, the aperture is too large in the hole set ink has certain hidden dangers of quality. When the PCB design file is converted into Gerber light drawing file, the window opening of the hole should be cancelled, otherwise the window opening will be made instead of the oil cover.

2.Open the window through the hole

Through the hole window refers to the hole welding plate is not covered with oil dew copper, surface treatment is gold or spray tin. The function of the window through the hole is to spray tin to the inner wall of the hole when the element is over wave soldering, which will increase the conduction capacity of the hole. The effect of the overhole window is the same as that of the plugin hole. There is no need to cancel the overhole window when transferring the Gerber file.

3, through the hole plug oil

Through the hole plug oil refers to through the hole wall inside the plug ink, the production of aluminum sheet will first plug the solder resistance ink into the hole, and then the whole plate printing solder resistance oil. The purpose of through-hole plug oil is to prevent short circuit caused by tin penetrating through the through hole through the component surface during PCB overwave soldering. The window opening of through-hole should also be cancelled when the design document is transferred to Gerber.

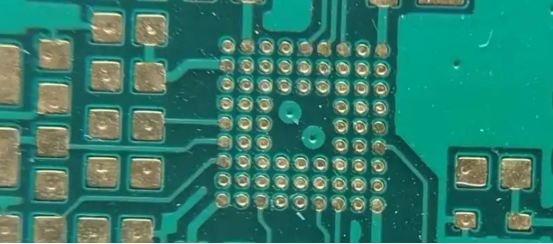

4. Resin plug hole

Resin plug hole refers to through the hole wall inside the resin, and then plated flat pad, suitable for any type of window through the hole or two window plate hole. For the purpose of resin plugging, from the perspective of technology, for example, the blind hole is drilled before pressing. If the hole is not plugged with resin, the PP glue pressed into the hole will flow into the hole, resulting in the laminating glue lack and bursting of the board. In terms of design, there are holes drilled on the welding pad. If the resin plug hole is not filled with electroplating, the welding area is less, which will lead to poor welding.

5.Fill holes with copper slurry

Copper paste hole filling refers to through the hole wall inside the copper paste, and then plated flat pad, suitable for any type of window through the hole or two window plate hole. The purpose of copper paste plug hole is to apply to the plate hole too much current, the cost of copper paste plug hole is much higher than the cost of resin plug hole. Design documents to cancel the hole opening window

Previous: PCB circuit board production process

Next: Structure of PCB board

Hot Products

Navigation

+86 134 0021 8776

Floor 9, Aupu building, No. 395 XinShi North Road, Shijiazhuang Hebei, China

Request a Quote