+86 134 0021 8776

+86 134 0021 8776

May. 08, 2025

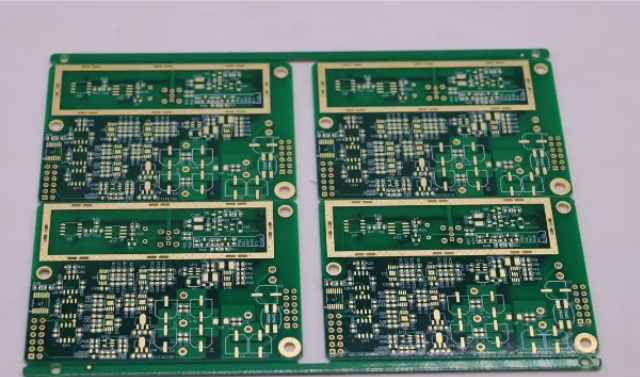

HDI circuit board is a high-density interconnect technology, which is characterized by reducing components such as line width, line spacing, blind holes, and stack holes to the micron level to achieve higher circuit density and performance. In the manufacturing process of HDI circuit board, the production of blind holes is a key link, especially the production of inner blind holes, which directly affects the quality and performance of the circuit board. The following is a detailed explanation of the blind hole process in the inner layer of the HDI circuit board.

1. Definition and classification of blind holes

In HDI circuit boards, blind holes refer to non-drilled holes, that is, only part of the board is connected to the level of the board, but not through the entire board. The blind hole is opposite to the through hole, and the through hole refers to the hole that is drilled through all layers. BLIND holes can be further subdivided into blind holes and BURIED holes, where the BURIED HOLE is not visible in the outer layer.

2.Preparation method

a. Drill tape selection and marking

In the process of making a blind hole, the reference point needs to be selected first, and the through hole (that is, a hole in the first drilling belt) is usually selected as the unit reference hole. A hole should be selected for each blind drilling belt, and the coordinates of its relative unit reference holes should be marked. In addition, it is necessary to note which drill tape corresponds to which layers to ensure accuracy in the production process.

b. Production of Pnl edge process holes

For HDI blind holes, all tool holes are drilled, especially rivet holes, which need to be brewed out to avoid alignment deviation. At the same time, the edge of the Pnl plate needs to be drilled in order to distinguish each plate.

3. Film modification

In the process of making blind holes, the modification of Film (light drawing film) is also an important step. Under normal circumstances, boards with board thickness greater than 8mil (without copper) go through the positive process, while boards with board thickness less than 8mil (without copper) go through the negative process (sheet). In addition, the inner independent Pad (pad) corresponding to the blind hole needs to be retained.

4. Blind hole filling technology

In the manufacturing process of HDI board, blind hole filling technology plays a crucial role, which is mainly divided into two processes: spot plating and whole plate plating.

Spot plating and hole filling plating

The process includes copper deposition, the whole plate electroplating, the use of dry film to cover the surface of the plate, and then make a blind hole plating pattern, and through exposure development, the blind hole position is opened, the other places are covered by dry film, and finally electroplating, the blind hole filling.

The whole plate is filled with holes and electroplated

This method is to use a special filling solution to fill holes after copper deposition, and fill the blind holes. This process can not only reduce the production cost, but also effectively improve the production quality of HDI board, improve the on-time delivery rate

5. Process design

The specific process design will vary according to the different needs of the HDI board. For example, for HDI boards with only blind holes in the inner layer, if the blind holes do not need to be filled, specific plating parameters can be used to ensure that the blind hole copper meets the requirements; If the blind hole needs to be filled, it is necessary to use a larger filling parameter to fill the blind hole, and then reduce the surface copper to the required thickness.

In summary, the production of the blind hole in the inner layer of the HDI circuit board involves several steps and technical details, including the selection of drilling tape, the production of Pnl edge process holes, Film modification and blind hole filling technology. These steps require precise operation and strict control to ensure the quality and performance of the final product.

Hot Products

Navigation

+86 134 0021 8776

Floor 9, Aupu building, No. 395 XinShi North Road, Shijiazhuang Hebei, China

Request a Quote