+86 134 0021 8776

+86 134 0021 8776

May. 16, 2023

Resistance is a device used to limit the flow of current in a circuit. Its basic unit is ohm (Ω). Common resistors in electronic components include thin film resistors and thick film resistors. The manufacturing process, performance and application scenarios of these two resistors are different.

First, film resistance

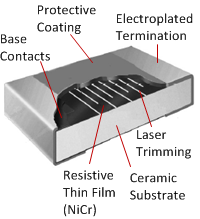

Thin film resistors are made by evaporation-like evaporation of resistive materials on the surface of insulating materials. Its manufacturing process is relatively complex, requiring a fine evaporation and film forming process in a vacuum environment. The commonly used insulating material is ceramic substrate. This resistance is often used in circuits requiring high precision and low drift, such as analog circuits, computers, communication circuits, etc.

The following are some characteristics of thin film resistance:

1. Thin film layer: generally less than 1μm, with good thermal diffusivity.

2, high precision: the precision of the film resistance can be 0.01% and 0.1%.

3. Low temperature coefficient: temperature coefficient refers to the change of resistance value with temperature within a certain temperature range. The temperature coefficient of the film resistance can be less than 10PPM/℃, even in the case of large temperature changes, the resistance value can remain stable.

4, small size: because the film layer is very thin, so the film resistance small volume, light weight.

5.High price: Due to the complexity of the manufacturing process and the characteristics of high precision and low drift, the price of the film resistance is relatively high.

Two, thick film resistance

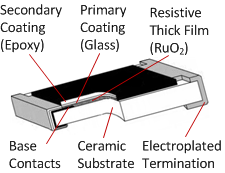

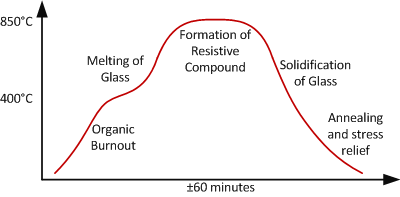

Thick film resistor, also known as: chip type fixed resistor. It is printed by a thick film process, usually using glass and plastic substrates as insulation materials. Thick film resistor is divided into high power resistor and precision resistor two types, mainly used in power supply, inverter, filter, distribution and other types of circuits.

Here are some characteristics of thick film resistors:

1. Film thickness: the film layer of thick film resistance is generally greater than 10μm.

2, low accuracy: the common accuracy of 1%, 5%, 10%, etc., the general accuracy can not meet the needs of high precision circuit.

3, high temperature coefficient: temperature coefficient is generally large, difficult to do low temperature drift.

4. Large size: thicker film layer, larger volume and weight of resistor.

5, low price: because the manufacturing process is relatively simple, so the price is relatively cheap.

Three, how to distinguish thin film resistance and thick film resistance

1, according to the film thickness. The film layer of thick film resistance is generally greater than 10μm, and the film layer of film resistance is generally less than 1μm.

2, according to the manufacturing process. Thick film resistors generally use screen printing process, thin film resistors use vacuum evaporation, magnetron sputtering and other processes.

3, according to the accuracy. The precision of thick film resistance is low, generally 1%, 5%, 10%, and so on, while the precision of film resistance can reach 0.01% and 0.1%.

4, according to the temperature coefficient. The temperature coefficient of thick film resistance is generally large, while the temperature coefficient of film resistance can be very low, such as 5PPM/℃, 10PPM/℃, etc.

5.Based on the application scenario. Thin film resistance is usually used in circuits requiring high precision and low drift, such as analog circuits, computers, communication circuits, etc. Thick film resistance is often used in power supply, inverter, filter, distribution and other types of circuits.

To sum up, although thin-film resistor and thick film resistor are both used to limit the current flow in the circuit, their manufacturing process, performance and application scenarios are different. When selecting resistors, the most suitable resistor should be selected based on the desired accuracy of the circuit, temperature drift and application scenario.

Hot Products

Navigation

+86 134 0021 8776

Floor 9, Aupu building, No. 395 XinShi North Road, Shijiazhuang Hebei, China

Request a Quote