+86 134 0021 8776

+86 134 0021 8776

May. 19, 2025

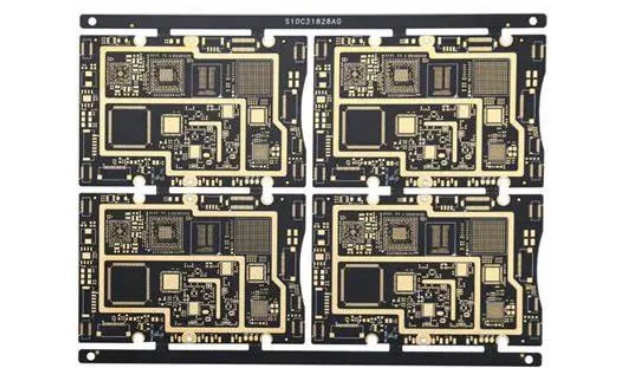

HDI (High Density Interconnect) refers to high-density interconnection. In the field of unmanned aerial vehicles (UAVs), UAVs HDI mainly refers to the adoption of high-density interconnection technology on the circuit boards of UAVs. This technology enables the circuit board to achieve more electronic component connections in a smaller space, and the circuits are more refined and complex.

Characteristics of Unmanned Aerial Vehicle HDI

Miniaturization: Drones need to carry various complex electronic devices, such as flight control systems, video transmission systems, sensors, etc., within a limited space. HDI technology can effectively reduce the size of circuit boards, providing the possibility for the miniaturization design of unmanned aerial vehicles. For instance, some small aerial photography drones can reach the size of a palm, and the HDI circuit board plays a crucial role in this. It can reduce the size of the originally large traditional circuit board, thereby lowering the overall volume and weight of the drone.

High performance: HDI boards can achieve higher wiring density and faster signal transmission speed. In unmanned aerial vehicles (UAVs), this is of great significance for high-speed signal transmission, such as high-definition video transmission signals and high-speed flight control signals. It can reduce signal delay and interference, making the control of unmanned aerial vehicles more precise and the image transmission clearer and smoother.

High reliability: Due to the adoption of advanced manufacturing processes, the connection of HDI boards is more secure, which can better resist the influence of factors such as vibration and shock that drones encounter during flight. For instance, when a drone is flying in a complex environment, such as in a windy environment or performing some highly maneuverable actions, the components and circuits on the HDI circuit board can maintain a stable connection state.

Application scenarios

Consumer-grade drones: Widely used in consumer-grade aerial photography drones. It enables unmanned aerial vehicles to integrate high-resolution cameras, stable flight control systems and long-distance video transmission systems within their compact fuselages. Consumers can use this type of drone for landscape photography, event recording, etc., and can view the shooting images in real time and control the flight of the drone through mobile phones and other devices.

Industrial-grade drones: For industrial-grade drones, such as those used in mapping, inspection and other fields, HDI technology can ensure efficient connections between high-precision sensors (such as lidar, multispectral cameras, etc.) and data processing units. In power inspection drones, the HDI circuit board enables the drone to accurately transmit the images and data of power lines back to the ground control station during flight, and can stably receive instructions from the ground control station to effectively detect line faults and other situations.

HDI circuit board manufacturing process

Micro-hole technology: In the manufacturing process of HDI circuit boards, micro-hole technology is used to create tiny holes on the circuit boards through methods such as laser drilling. The diameters of these holes can reach tens of micrometers or even smaller. These micro-holes are used to achieve electrical connections between different layers. Compared with traditional vias, micro-holes occupy less space and can increase the wiring density.

Lamination manufacturing: The lamination method is used to construct multi-layer circuit boards. This method increases the number of layers of the circuit board by continuously adding insulating and conductive layers on the basis of the existing inner layer circuits. On each layer, fine circuit layout can be carried out. Finally, through processes such as lamination, the multiple layers are combined together to form a complete HDI circuit board.

Development trend

Higher integration: As the functions of drones continue to expand, such as adding artificial intelligence recognition modules and obstacle avoidance systems, the integration requirements for circuit boards will be higher. HDI technology will develop in the direction of being able to integrate more functional modules in a smaller space.

The combination with new materials: In the future, it may be combined with new electronic materials, such as graphene and other materials with excellent electrical properties. These new materials, when applied to HDI circuit boards, are expected to further enhance the performance of the circuit boards, such as improving conductivity and reducing power consumption, thereby improving the overall performance of unmanned aerial vehicles.

Previous: What are the five major categories of wires and cables

Next: Detailed Analysis of Electromagnetic Interference (EMI) in Unmanned Aerial Vehicle Wiring Harnesses

Hot Products

Navigation

+86 134 0021 8776

Floor 9, Aupu building, No. 395 XinShi North Road, Shijiazhuang Hebei, China

Request a Quote