+86 134 0021 8776

+86 134 0021 8776

Jun. 12, 2025

First, the preparation of copper and aluminum raw materials

The first step in the manufacturing of wires and cables is to prepare raw materials. Copper and aluminum are two main raw materials for wires and cables, among which copper has the best electrical conductivity and is widely used in high-precision electrical appliances. Aluminum has the advantages of light weight and low price, and is widely used in general electrical appliances. Wire and cable manufacturing enterprises will prepare the required copper and aluminum raw materials according to the order demands.

Second, drawing of copper and aluminum single wires

After preparing the copper and aluminum raw materials, the manufacturing of wires and cables enters the wire drawing process. Wire drawing is the process of gradually reducing the diameter of copper and aluminum raw materials through a series of wire drawing machines and dies to form the required wire diameter. The wire drawing process is one of the fundamental processes in the manufacturing of wires and cables. Its precision and quality directly affect the performance and quality of the final product.

Third, the annealing process

copper and aluminum monofilaments are heated to a certain temperature to enhance their toughness and reduce their strength through recrystallization, thereby meeting the requirements for conductive cores in wires and cables. The key to the annealing process is to prevent the oxidation of copper wire.

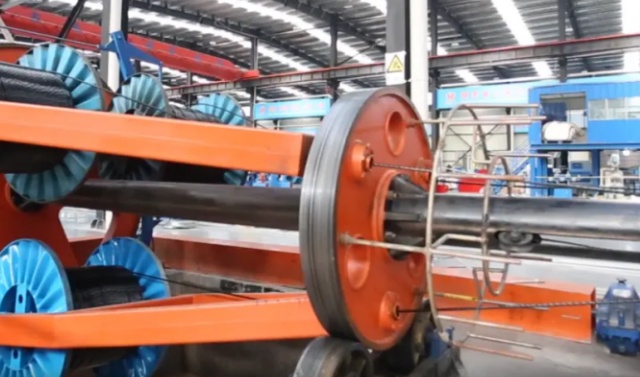

Fourth, the conductor stranding process

Conductor twisting is the process of twisting multiple drawn wires together in a certain pattern to form a conductor. According to the twisting form of the conductive wire core, it can be divided into regular twisting and irregular twisting. Irregular twisting can be further classified into bundle twisting, concentric compound twisting, and special twisting, etc. The purpose of the stranding process is to enhance the overall strength and stability of the conductor, and at the same time, it can reduce the outer diameter of the cable.

Fifth, insulation layer extrusion

After the stranding is completed, the insulation layer is extruded. By using a screw of a specific shape to rotate in a heated barrel, the plastic sent from the hopper is extruded forward to ensure uniform plasticization. Through the die head and molds of different shapes, the plastic is extruded into continuous plastic layers of various shapes as required, and then wrapped around the core wire and cable.

The insulation layer is one of the core components of wires and cables. Its function is to protect the wires and cables from external environmental and mechanical damage, and at the same time prevent current leakage.

Sixth, twist the insulated wire core together

The process of twisting insulated wire cores together according to certain rules, including filling the gaps between the cores during twisting and wrapping tape around the cable core, is called cable forming. The purpose of cabling is to meet the multi-core requirements, maintain the stability of the cable structure, increase the flexibility of the cable and reduce losses.

Seventh, install the outer sheath

The outer sheath is the structural part that protects the insulation layer of wires and cables from erosion by environmental factors. The main function of the outer sheath is to enhance the mechanical strength of wires and cables, prevent chemical corrosion, moisture, water immersion, and prevent cable combustion, etc. According to different requirements for cables, plastic sheaths are directly extruded using extruders.

Eighth, finished product inspection, acceptance, packaging and warehousing

After the elaborately crafted products are completed in manufacturing, they will undergo a series of rigorous and meticulous inspection procedures. These processes will be carried out in a dedicated factory, which is equipped with advanced equipment and instruments to ensure that the quality and performance of the products meet national standards. After passing the inspection, these finished products can be officially released from the factory and enter the sales stage.

Hot Products

Navigation

+86 134 0021 8776

Floor 9, Aupu building, No. 395 XinShi North Road, Shijiazhuang Hebei, China

Request a Quote