+86 134 0021 8776

+86 134 0021 8776

News

Oct. 21, 2025

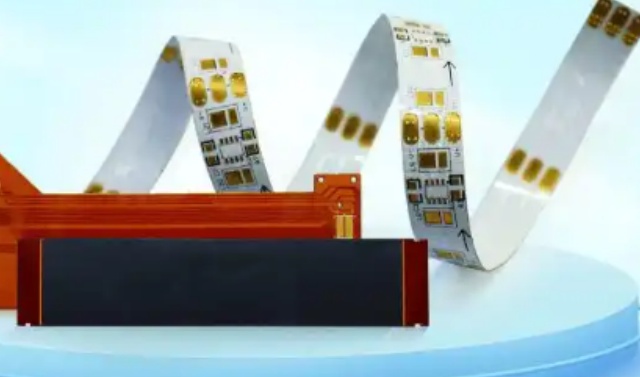

With the development of electronic technology, Flexible Printed Circuit Board (FPC), with its characteristics of being lightweight, flexible and space-saving, has become a "necessity" for modern electronic devices. Flexible circuit boards play a significant role in both smartphones and smartwatches, as well as in automotive electronics and medical devices. This article will take you on a deep dive into the basic knowledge, structural materials, manufacturing processes, application fields, and future development trends of flexible circuit boards.

I. What is a flexible circuit Board?

Flexible circuit boards, abbreviated as FPC, are a type of circuit board that can be bent and folded. Different from traditional rigid circuit boards, they use flexible materials, enabling them to maintain stable electrical performance in scenarios where bending, curling, or even folding is required. Flexible circuit boards can arrange circuits in various complex shapes and Spaces, and thus are widely used in modern miniaturized and integrated devices.

Ii. Core Structure and Materials of Flexible Circuit Boards

The structure of a flexible circuit board includes a flexible substrate, a conductive layer, an insulating protective layer, and a covering film, etc. The main materials are as follows:

1. Flexible substrate: Polyimide (PI) or polyester (PET) are usually used. Among them, PI material has better high-temperature resistance and chemical resistance, and is more suitable for equipment in harsh environments.

2. Conductive layer: The commonly used layer is the copper foil layer, which forms a conductive circuit after being etched in a pattern.

3. Covering film: To protect the surface of the circuit board and enhance its durability, a protective film is usually applied, which can effectively prevent circuit damage and external interference.

Iii. Advantages of Flexible Circuit Boards

1. Excellent flexibility: Flexible circuit boards can be bent and folded at will, making them suitable for scenarios where the internal space of the equipment is relatively small.

2. Lightweight and space-saving: Compared with traditional circuit boards, its base material is thinner and its weight is lighter, which helps to reduce the overall weight of the equipment.

3. High reliability: The flexible circuit board is firmly connected and remains stable in high-vibration and mobile equipment, which can reduce equipment failures caused by poor contact.

4. Flexible design: It can achieve a more free layout, is suitable for multi-layer wiring design, and improves space utilization.

Iv. Manufacturing Process of Flexible Circuit Boards

The manufacturing process of flexible circuit boards is more refined compared to traditional rigid circuit boards and typically includes the following steps:

1. Pattern transfer: Transfer the circuit pattern onto a flexible substrate through steps such as exposure and development.

2. Etching: Chemical etching removes unwanted copper foil to form the required circuit pattern.

3. Covering film adhesion: Apply a protective film on the surface of the circuit layer to enhance anti-interference and waterproof and dustproof performance.

4. Hole opening and pad treatment: Make necessary holes to provide installation and soldering positions for electronic components.

This process flow can ensure that the flexible circuit board is lightweight in structure, but its functionality is not compromised in the slightest.

V. Wide Application of Flexible Circuit Boards

FPC (Flexible Printed Circuit) is a printed circuit board made of flexible substrates, which has high flexibility and bendability, and is widely used in many fields.

1.In the field of consumer electronics

FPC products have significant applications in the field of consumer electronics. For instance, in electronic devices such as smart phones, tablets and laptops, FPC products are used as flexible connection lines to link various components and transmit signals. The flexibility and bendability of FPC products enable them to adapt to the design requirements of devices of different shapes and sizes, providing a better user experience.

2. Automotive electronics field

With the rapid development of automotive electronics, the application of FPC products in the automotive electronics field is becoming increasingly widespread. FPC products can be used in electronic devices such as instrument panels, central control panels, seat regulators and in-car entertainment systems inside automobiles to achieve functions such as signal transmission, power supply and data processing. FPC products feature a compact size and good temperature resistance, which can meet the special requirements of automotive electronic devices.

3. Medical equipment field

FPC products also have extensive applications in the field of medical equipment. Due to the softness, thinness and foldability of FPC products, they can be conveniently embedded in various medical devices, such as pacemakers, blood glucose meters and blood pressure monitors. FPC products can provide reliable signal transmission and power supply, while meeting the requirements of medical equipment for high hygiene and durability.

4. Industrial control field

The industrial control field is another important application area for FPC products. FPC products can be used on control panels, sensors, communication modules and other devices in industrial control systems. The flexibility and reliability of FPC products enable them to adapt to complex conditions such as vibration and temperature changes in industrial environments, providing stable signal transmission and reliable power supply.

5. Aerospace field

Due to the characteristics of FPC products such as being thin, light, flexible and reliable, they are also widely used in the aerospace field. FPC products can be used in the circuit connection, data transmission and control systems of aerospace equipment. The reliable performance and anti-vibration capability of FPC products enable them to adapt to complex aerospace environments and harsh working conditions, ensuring the normal operation of spacecraft.

Vi. Future Development Trends of Flexible Circuit Boards

With the development of 5G, the Internet of Things and AI technologies, flexible circuit boards will play a more important role in electronic devices. In the future, flexible circuit boards will develop in the following directions:

1. Higher integration: Through flexible hybrid electronics (FHE) technology, multiple functions are integrated into flexible circuits, providing more intelligent solutions.

2. Better environmental adaptability: High-temperature and corrosion-resistant materials will gradually be applied to meet the application requirements in harsh environments.

3. Application of new materials and manufacturing technologies: As technologies such as laser cutting and 3D printing gradually mature, they will provide more efficient methods for the production and manufacturing of flexible circuit boards.

4. In-depth application in the medical and health fields: The application prospects of flexible circuit boards in wearable devices and micro medical devices are broad, which will further enhance the portability and intelligence level of medical devices.

Flexible circuit boards, with their unique flexibility, lightness and high reliability, have become important components in the design of electronic products. Understanding the characteristics, structure and application fields of flexible circuit boards can enable us to have a deeper understanding of the future development of electronic technology. Under the trends of intelligence and miniaturization, flexible circuit boards will undoubtedly continue to expand their application scenarios and become one of the key technologies for smart devices.

Previous: High-speed copper cable connection technology: Numerous advantages and a promising industry outlook

Next: The application and development of flat cables and their structural advantages

Hot Products

Navigation

+86 134 0021 8776

Floor 9, Aupu building, No. 395 XinShi North Road, Shijiazhuang Hebei, China

Request a Quote