+86 134 0021 8776

+86 134 0021 8776

Apr. 25, 2023

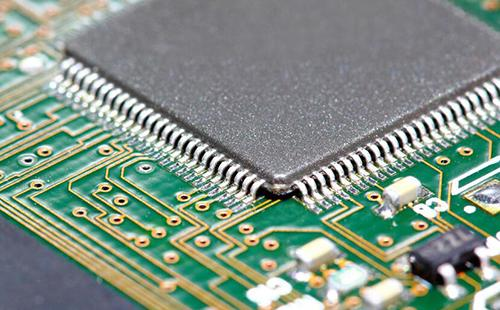

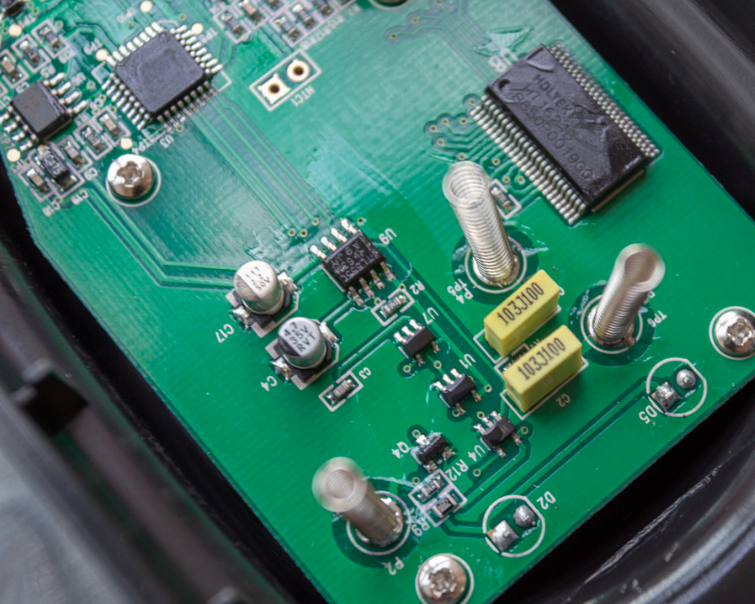

Reflow soldering is not unknown in the field of electronics manufacturing. The components on various boards used in electronic equipment are welded to the circuit board by reflow soldering process. Inside the reflow soldering machine, there is a heating circuit that heats air or nitrogen to a high enough temperature to blow the circuit board with attached components. Let the solder on both sides of the component melt and bond to the motherboard.

Flux is a product used in the process of reflow welding. Its function is to help reflow welding to complete the perfect welding of components and pcb pads to the maximum extent, mainly for improving the welding process of smt patches. However, if the reflow welding machine has been used for a long time, there will be flux residue, which will cause serious problems if not properly handled.

First, the residual flux may cause problems.

1. It is corrosive to the substrate;

2. Reduce electrical conductivity, resulting in migration or short circuit;

3, resin residue is too much, adhesion dust and debris;

4, affect the use of products, reliability.

Second, the solution of flux residual countermeasures.

1, choose the appropriate flux, activity should be moderate;

2. Use flux that can form protective film after welding;

3. Use the flux without resin residue after welding;

4. Use low solid content no-clean flux;

5. Clean reflow welding equipment after welding.

Previous: What is the difference between the manufacturing process of thin film and thick film resistors?

Hot Products

Navigation

+86 134 0021 8776

Floor 9, Aupu building, No. 395 XinShi North Road, Shijiazhuang Hebei, China

Request a Quote